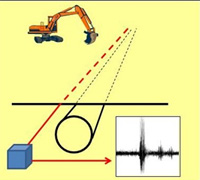

A unique photo-acoustic system that immediately warns for the threat of damage to the pipeline caused by digging activities, drilling and vandalism. Any activity generates acoustic energy ("noise") which is transduced to the silica molecules of a glass fiber. A reading unit continuously launches a high frequency light pulse through a fiber that is running parallel to the pipeline under observation and analyses the backscattered spectrum. Any activity as far as 10m from the pipeline is picked up by the fiber and is visible from the shift in the backscattered light. The system also shows the location of the activity with an accuracy of one to a couple of meters, even if the pipeline is up to 50kms long! And as every activity has its own acoustic "foot print", it is even possible to see what activity is taking place!

Already existing telecom fiber cables running parallel adjacent to the pipeline can sometimes be utilised which can lead to a considerable saving on capital investment.

Download: